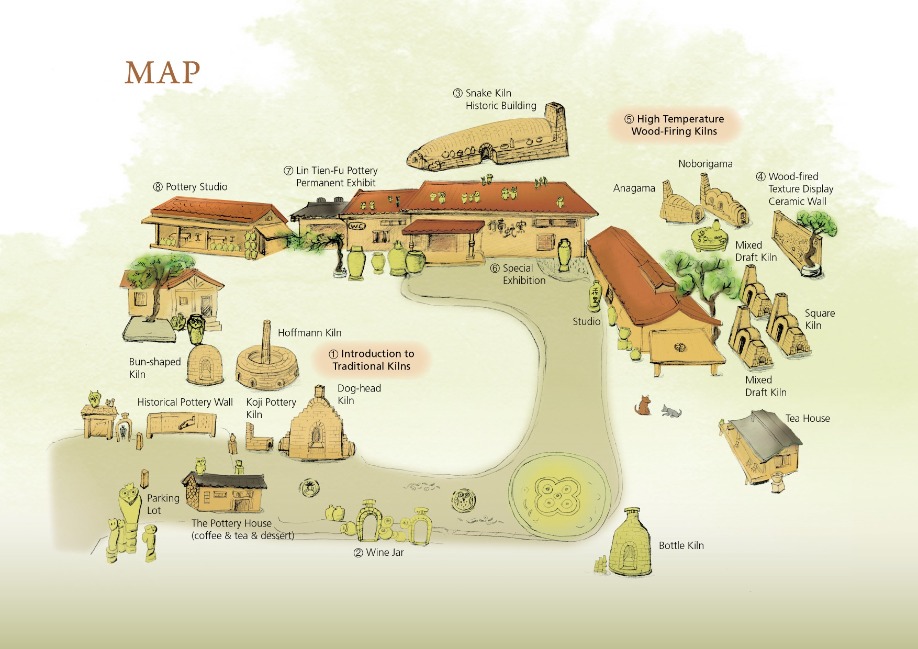

Pottery House

Located by the entrance of the Zhunan Snake Kiln grounds. Sells hand-made ceramics, small objects, ceramics history books, and pour over coffee.

These kilns were used to fire ceramics at various times in Taiwan and witnessed the evolution of Taiwanese society and culture as well as that of the ceramics industry. These traditional kilns were the cradle from which Taiwanese ceramics developed. From historical investigations to research and publication, to finally rebuilding the actual kilns, The Lost Ancient Kilns is an important exhibition that educates and offers a cultural tour of the history of Taiwanese kilns.

Kiln classification

Bottle Kiln

The bottle kiln is so named for its shape.

It has an updraft flame path, and is not very common in Taiwan.

It was used to fire refractory bricks in the early days. Bottle kilns in Europe were used to fire bowls, plates and tiles.

Mantou Kiln

Mantou Kiln is also called a tile kiln. In northern Taiwan it is called baozi (steamed bun) kiln, because the top is covered in dirt and looks like a bun from afar. In the south, it is called a turtle kiln because the top is covered with tiles and resembles a turtle shell from afar. It is used exclusively for firing building materials for traditional buildings, such as red bricks, thin tiles, and Chinese window frames. The kiln has a semi-downdraft flame path, and mainly burns wood or rice husk for fuel.

Round Kiln

The round kiln, also known as the steamer kiln or wheel kiln, is used to fire red bricks and is a continuous kiln. It later evolved into the larger Hoffmann Kiln. Currently, a downscaled version is placed on the grounds for cultural education purposes, while also serving as a round bench for resting.

Daruma kiln

The Daruma kiln is also called the black tile kiln. The kiln also looks like a dog's head, so it is also commonly known as the dog head kiln. The Japanese people call it the Daruma kiln think it resembles the monk meditating. Mainly used to produce Japanese smoked tiles.

During the Japanese occupation, the black tile kiln was once popular due to the high demand of the black rooftop tiles as Japanese style buildings popped up all over Taiwan. There was a black tile kiln in nearby Zaoqiao, Miaoli, though as the industry was made obsolete by the times, so to did the black tile kiln.

The traditional black tile kiln uses coal as fuel and has openings for feeding coal on both sides. During the last stages of firing, water would be poured in to produce large amounts of black smoke inside the kiln, smoking the tiles and turning it black.

Cochin Kiln

Cochin Kiln is used mostly for Taiwanese temple decorations, mostly about myths and folklores, and made of low temperature, glazed, soft ceramics.

Cochin ware is mostly fired in electric kilns now. In the old days, the kilns were built in the square in front of the temple to fire figures for the temple. Once the temple construction was completed, the little kiln would be removed. Consequently, all Taiwanese traditional wood-fired Cochin kilns have been lost.

Hua-Shi Kiln

In 1997, Zhunan Snake Kiln kiln master Lin Jui-Hwa followed in his father's footsteps to design and build a kiln for high temperature wood-firing, using refractory material, combing features of the snake kiln and the anagama. Since the kiln is small, its temperature is easy to control, and the wood-firing temperature could be raised to new heights for control of all the possible changes in quality and texture. It once reached a high temperature of 1447 degrees Centigrade.

The naming of Hua-Shi (化十) kiln: Kiln master Lin Jui-Hua's Hua (華) written in Simplified Chinese is 化十. In addition, the kiln master is very fond of fossils (also pronounced Hua-Shi in Mandarin Chinese), and wants to create ceramics as beautiful as fossils. Hence the name Hua-Shi kiln.

Ruyi Noborigama

Noborigama is a specialty of traditional kilns in Miaoli. Also called a chambered climbing kiln, Zhunan Snake Kiln's Ruyi Noborigama is based on a design concept by Lin Jui-Hwa that combines traditional noborigama with contemporary wood-firing. It is a modified noborigama with three chambers. With a semi-downdraft flame path, the special feature of this kiln is that after the front chamber has finished firing, the second and third chambers can be fired from the sides, with each controlled at a different temperature. Named Ruyi by Lin Tien-Fu to wish every firing to proceed as hoped.

Fang Hua Kiln

World's Highest Temperature Wood-Fired Kiln

The traditional rectangular kiln is rectangular, with a smoke channel below the floor and a downdraft flame path. It is the most advanced craft in mankind's history of using fire. Fang Hua kiln is modified from the coal-burning rectangular kiln to be optimized for high temperature wood firing. Lin Jui-Hua built the kiln himself, brick by brick, and was able to set a record of 1418℃ during the first firing on June 24, 2012. It even set the Guinness World Record for highest temperature in a wood-fired kiln at 1563℃ in 2016.

Eleven Studies Pottery Classroom